Industrial and Factory Automation Market - Forecast(2020 - 2025)

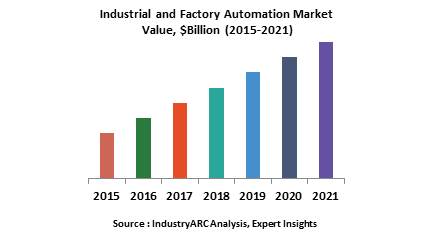

Increasing usage of machines, the demand for high quality products with high volume production in various industries, and increasing installation and adoption of smart devices are the factors driving the growth of the industrial and factory automation market during the forecast period 2019 to 2025. Smart devices can communicate with each other within the factory and also with the cloud. According to the fresh market research report from IndustryARC, this is the major factor which is opening up industrial and factory automation market which already has a market size of nearly $5 billion in 2018, and the demand for the same is projected to grow at a notable CAGR of 12% during the forecast period.

Industrial and factory automation refers to the automation of manufacturing, and material handling by using smarter manufacturing infrastructure. Industries are implementing automation to increase productivity and reduce labor costs. Embedded vision is a technology which optimizes the factory production floor in areas such as raw materials handling and assembly. Factory automation uses the pneumatic technology, because it operates at much lower than hydraulic technology. With the adoption of automation, control loops were added to machine operation. These control loops are two types, open control loops that allow for human input and closed loops which are fully automated. The main advantage of these control loops are increase in production, and quality, and reduce in errors.

- The Cobots or Collaborative Robots are replacing the human jobs which are either too repetitive or dangerous; allowing the human workers to focus on other easy operations in the industries.

- International Data Corporation (IDC) estimates that by 2018, 30% of all new robotic deployments will be smart collaborative robots that operate three times faster than today’s robots and are safe for work around humans.

- Cobots are especially suitable for small and medium-sized companies, which account for 70% of global manufacturing, as they give human workers new tools to complete tasks more quickly, efficiently, and with greater insight than ever before.

Comments

Post a Comment